Build Episode 2

[size=14pt]

The Steam Pipe[/size]

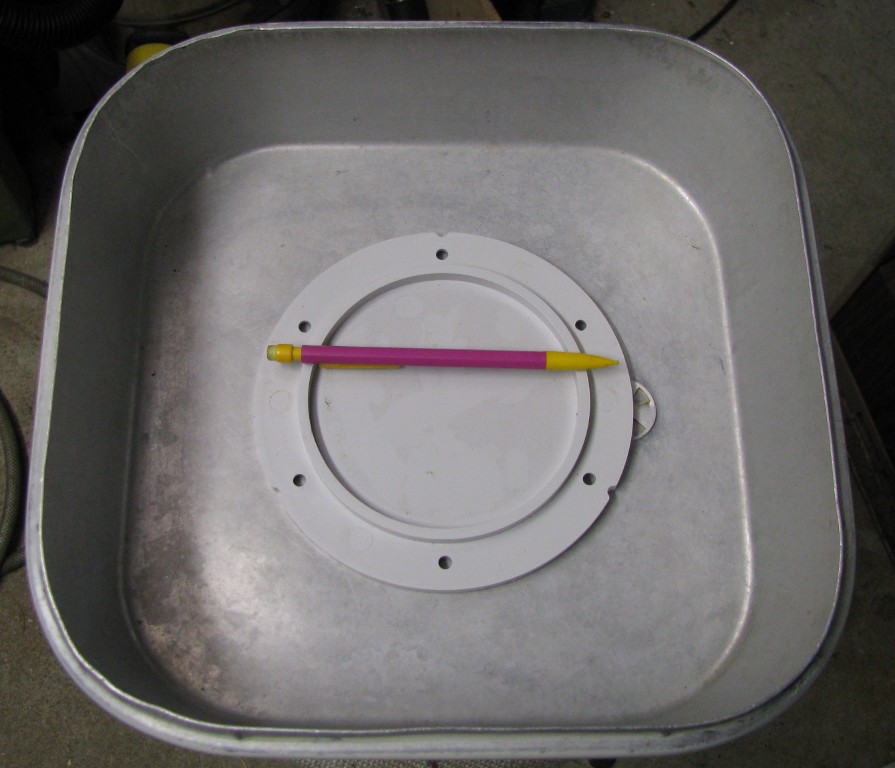

Deburring of the PVC pipe ends; inside with the blue Shaviv deburring tool, outside with the disc sander;

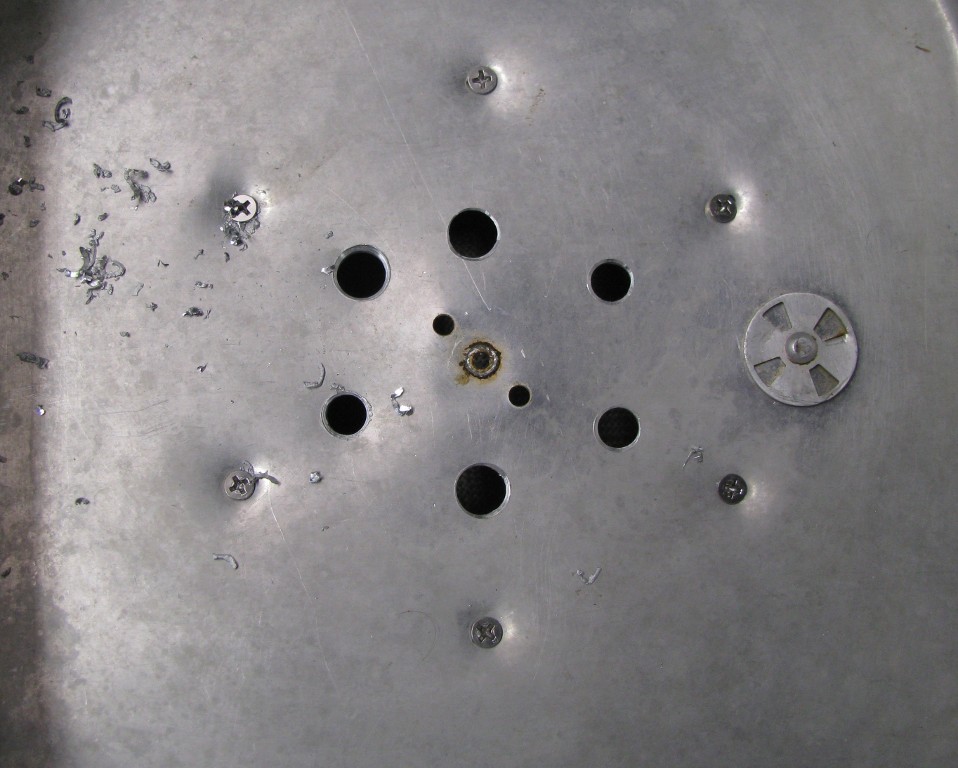

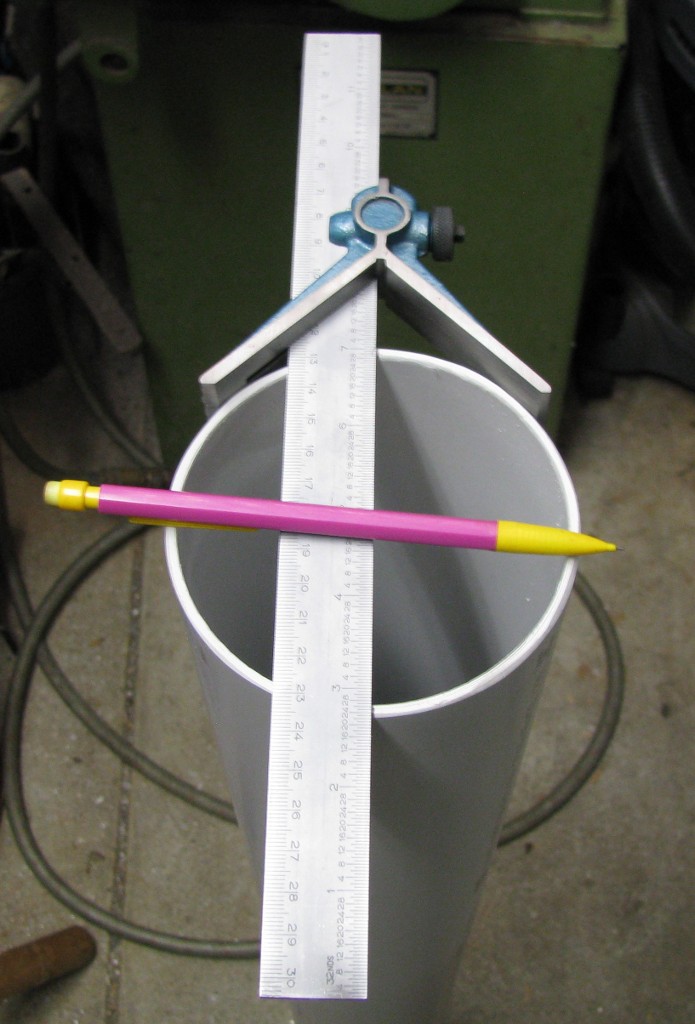

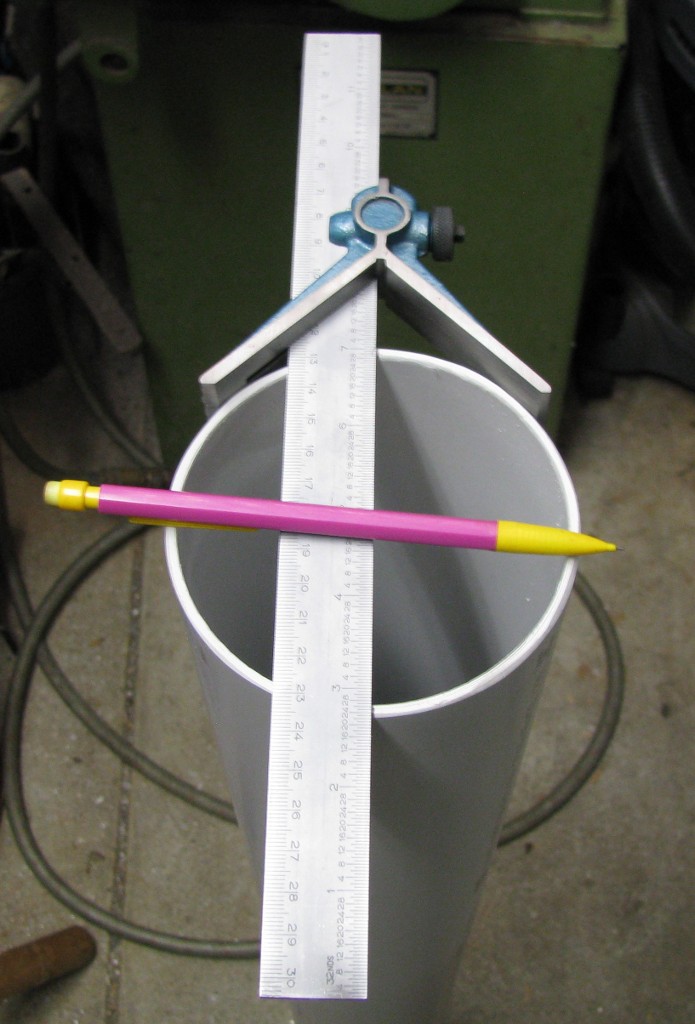

Marking the centrelines for V-grooves in the top of the pipe, to locate the cross-bar, so as to suspend barreled actions/parts from it;

The V-grooves, cut with a 'cant saw' file [if anyone doesn't know what this is, I can post a pic];

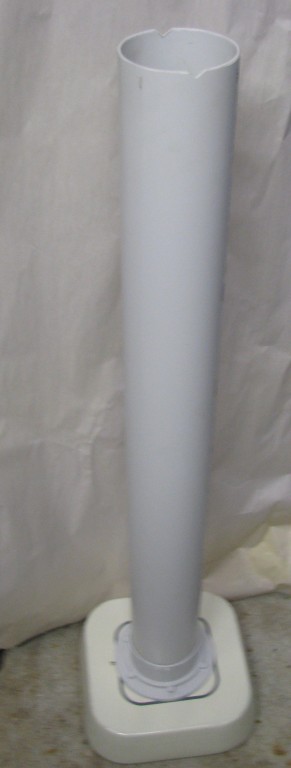

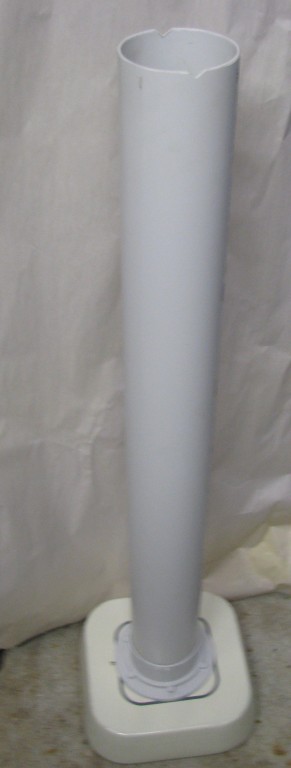

The finished lid/pipe assembly - don't see any need to glue this up, at this time;

The crossbar components; wood dowel would also work, but as I had some 1/2" OD 316 stainless milking machine tubing...

The crossbar in place. The hose is just a piece of 1/2" garden hose; it prevents the crossbar sliding sideways under load, and dropping the suspended part/s down the pipe;

The 'apparatus' set up, ready for its first live steam;

We have steam!

This job took about an hour, start to finish.

The advantage of using a leccy frypan, is that it is closed-loop controlled by a thermostat [not an open-loop simmerstat/energy regulator], and it's very easy to control the steam production rate.

While steaming parts, it's usual to cover the top of the pipe with a towel, or aluminium foil.

I may cut the V-grooves deeper at some time, to allow the trap lid to be used as a loose lid, if I feel like it.

This setup also doubles as a 'damp cabinet' for the rusting steps in the rust blue process; just fill the pan up with cold water!