My attempt at bedding an action

Posted: Wed Jun 04, 2014 10:05 pm

I have always said that I was going to bed the boyds stock on my Stevens 200 in 223 but to be honest it shot well enough and I have never really been bothered until last time I went spotlighting and halfway through the night I missed a few shots that I was sure should of hit causing me to doubt both my ability and the rifle and started aiming for chest shots rather than head.

I went to the range on the weekend and a few shots on paper saw it shooting well but not not like it normally does with a few erratic shots. Closer inspection showed that one of the action screws had loosened a fraction and the barrel could move from one side of the barrel channel to the other fairly freely - not ideal.

Then on Monday night at touch footy I rolled my ankle and doing a pretty good job the next morning struggling to work and unable to put on a work boot I called in to work to let them know I wouldn't be in. Now I am the sort of guy who will make the most of a bad situation and having a whole day free I figured now or never to bed the action. I thought I had all the bits I needed bar a set of stock screws but a quick trip to the screw supplier saw me back home with a 100mm long bolts with the same thread for the grand total of $3. The horizontal bandsaw made quick work of removing the hex head and I was left with there

After plenty of googling and youtubing I was feeling confident enough to get stuck into it and pulled the rifle apart stripping off the trigger mech and the mag box - which is a major PITA

This is what the inletting looked like before I got stuck into it

And after it was attacked with the dremel - plenty of material removed from behind the recoil lug as well as around the action screws etc

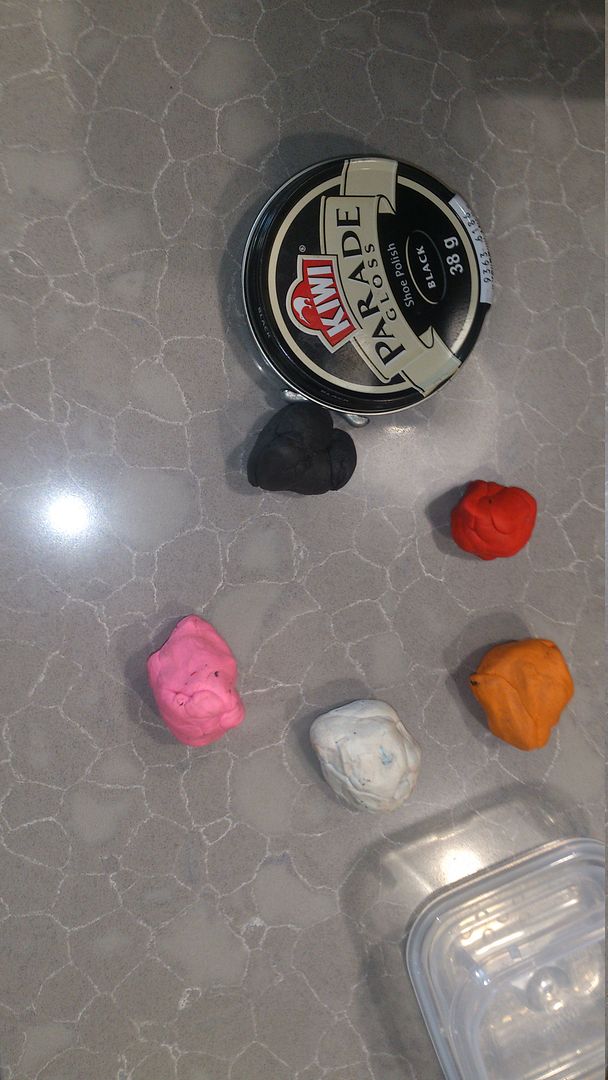

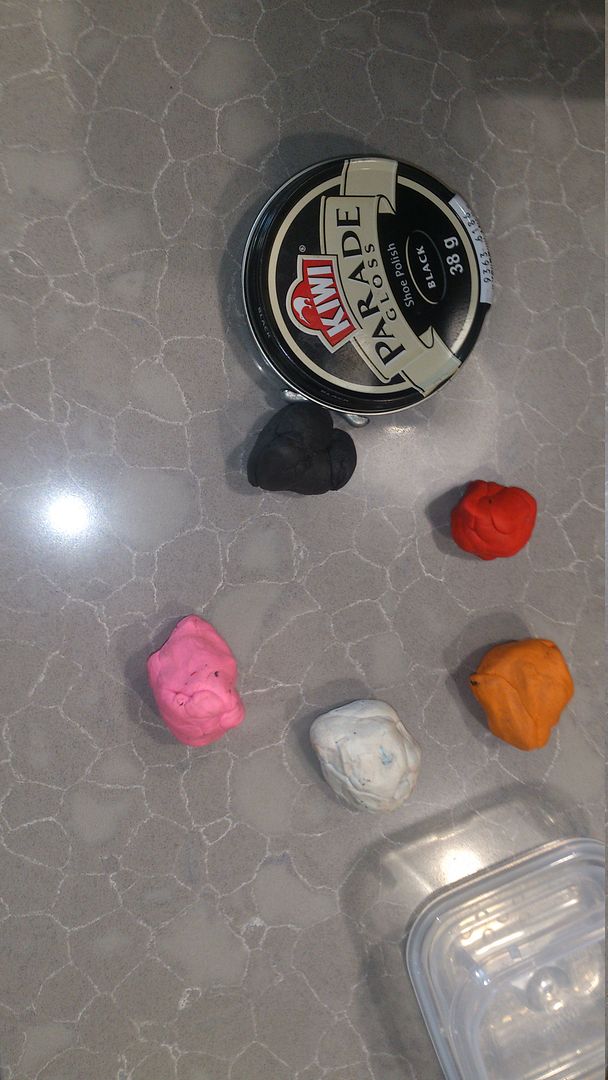

Then I realised I had forgotten to stop of at bunnings on the way home and get something to fill all the holes in the action and stock I didn't what to be filled with epoxy. Not to worry I live with little people who have a craft box and after a short rummage I found some plasticine. Also pinched a couple of paddle pop sticks to mix my epoxy, I knew these kids would come in handy for something.

Then I got carried away and forgot to take any photos but I filled all the voids in the stock and action with plasticine and put some masking tape along the stock to make cleaning the epoxy off a little easier. I also put 2 layers of masking tape under the tang as the stevens action only has 2 action screws - basically one infront and behind the mag box and by floating the tang it meas there isn't any undue stresses on the rear of the action - or so the internet tells me. The whole action and masking tape etc was given a few coats of kiwi shoe polish - black cause that was what was in the cupboard.

I used JB weld to bed the action mostly because I can get it from jaycar which is just up the road from work. I think it was about 15 bucks. It was fairly runny but was still fine to work with. I did read that you can let it set and thicken a little before using it.

Then I got to this stage

Once it was together I wrapped a few layers of electrical tape around it to hold it together and cleaned up any epoxy that had squeezed out. Then waited and hoped that I hadn't just glued the whole thing together for eternity.

Then after the appropriate time I undid all the tape, gave it a few good solid taps with the palm of my hand on the barrel and it popped free - relieved is an understatement.

Looked pretty good, good coverage where it needed to be and only pulled the corner of a few mm on the side of the action - I can live with that.

After a bit of a clean up with various files and the dremel, then a wipe down with acetone.

Actually turned out much better than I was expecting and I am pretty chuffed with myself. I have screwed it all back together and can't wait to punch a few holes and see if it has made much difference.

Cheer

James

I went to the range on the weekend and a few shots on paper saw it shooting well but not not like it normally does with a few erratic shots. Closer inspection showed that one of the action screws had loosened a fraction and the barrel could move from one side of the barrel channel to the other fairly freely - not ideal.

Then on Monday night at touch footy I rolled my ankle and doing a pretty good job the next morning struggling to work and unable to put on a work boot I called in to work to let them know I wouldn't be in. Now I am the sort of guy who will make the most of a bad situation and having a whole day free I figured now or never to bed the action. I thought I had all the bits I needed bar a set of stock screws but a quick trip to the screw supplier saw me back home with a 100mm long bolts with the same thread for the grand total of $3. The horizontal bandsaw made quick work of removing the hex head and I was left with there

After plenty of googling and youtubing I was feeling confident enough to get stuck into it and pulled the rifle apart stripping off the trigger mech and the mag box - which is a major PITA

This is what the inletting looked like before I got stuck into it

And after it was attacked with the dremel - plenty of material removed from behind the recoil lug as well as around the action screws etc

Then I realised I had forgotten to stop of at bunnings on the way home and get something to fill all the holes in the action and stock I didn't what to be filled with epoxy. Not to worry I live with little people who have a craft box and after a short rummage I found some plasticine. Also pinched a couple of paddle pop sticks to mix my epoxy, I knew these kids would come in handy for something.

Then I got carried away and forgot to take any photos but I filled all the voids in the stock and action with plasticine and put some masking tape along the stock to make cleaning the epoxy off a little easier. I also put 2 layers of masking tape under the tang as the stevens action only has 2 action screws - basically one infront and behind the mag box and by floating the tang it meas there isn't any undue stresses on the rear of the action - or so the internet tells me. The whole action and masking tape etc was given a few coats of kiwi shoe polish - black cause that was what was in the cupboard.

I used JB weld to bed the action mostly because I can get it from jaycar which is just up the road from work. I think it was about 15 bucks. It was fairly runny but was still fine to work with. I did read that you can let it set and thicken a little before using it.

Then I got to this stage

Once it was together I wrapped a few layers of electrical tape around it to hold it together and cleaned up any epoxy that had squeezed out. Then waited and hoped that I hadn't just glued the whole thing together for eternity.

Then after the appropriate time I undid all the tape, gave it a few good solid taps with the palm of my hand on the barrel and it popped free - relieved is an understatement.

Looked pretty good, good coverage where it needed to be and only pulled the corner of a few mm on the side of the action - I can live with that.

After a bit of a clean up with various files and the dremel, then a wipe down with acetone.

Actually turned out much better than I was expecting and I am pretty chuffed with myself. I have screwed it all back together and can't wait to punch a few holes and see if it has made much difference.

Cheer

James